Ingeus Organisation Award – Continuous Improvement Strategy Execution

Ingeus is a leading people services provider, delivering long-term, impactful projects to enable better

lives. Working for commissioners at national and regional level, and hundreds of partner

organisations it delivers programmes across the employability, health, youth, and justice sectors. It

employs 2,300 people, based remotely and across 100+ UK office locations.

As a customer-focused business our goal is to deliver excellent customer service and achieve high-

quality performance outcomes. Taking time to understand our customers is essential to ensure our

services meet their needs.

Our Transformation Director Lisa Jasper identified that a continuous improvement culture and

strategy was required to enable Ingeus to deliver excellent customer service and achieve

consistently high-quality performance outcomes.

Increasingly, service commissioners including Ministry of Justice, Department for Work and Pensions

and the NHS have expectations that require us to invest in continuous improvement and a

structured methodology.

With this in mind, in 2021, Ingeus UK embarked on a journey to create and embed a culture of

Continuous Improvement (CI) across all division, contracts, and services. In our mission to harness

the talents of our contrasting teams, and to continuously improve, we launched our three-year

Continuous Improvement Strategy in October 2021.

Key milestones set and delivered included

- Increasing Leadership and All staff Engagement in CI.

- Increasing CI capability across Ingeus with the aim of four per cent of the Ingeus employee

population accredited as Change Agents. - Implementing a programme of process standardisation with a supporting framework to

eliminate variation. - Mapping, standardising and enhancing our Customer Journeys

- Aligning continuous improvement activity with Compliance, Quality, Assurance and Risk

activity. - Introducing Visual management.

- Launching an internal accredited Continuous Improvement Academy for over 2300

employees. - Create a CI Toolkit accessible to all employees and Change Agents to enable them to identify

and deliver improvements.

Activity

Fully supported and sponsored by Ingeus Executive team our Transformation Director Lisa Jasper

launched a three-year CI Strategic plan. The strategy was designed to create and embed a

continuous improvement culture to enable Ingeus UK to deliver excellent customer service and

achieve high quality performance outcomes. Activities were carried out using Lean and Six Sigma

principles.

- The programme commenced with the creation of an Ingeus CI House used as an easy visual prompt

for colleagues to understand and engage with the strategy. Using the CI House, the team set out the

strong foundations including a Continuous Improvement Academy, Governance and Quality

Assurance Framework, and Leadership and Engagement, supported by three pillars: Standardisation,

Visual Management and Continuous Improvement.

In April 2021 a skills audit across all teams established only seven employees had a qualification in a

CI Methodology and highlighted that 68 per cent of employees had no CI experience. Baseline data

indicated a lack of capability across the business. Root cause analysis around capability and CI

experience was attributed to a lack of strategic and enterprise level CI awareness, engagement, and

training opportunities for all levels, including Senior Leaders.

Key strategic solutions included: - Effective comms and awareness for leaders and staff to introduce CI strategy including

monthly CI updates for the Executive team, detailing strategy execution, and feeding back - Executive expectations to leaders and teams4% target for minimum team CI capability reviewed frequently to ensure capability is being

maintained - Investment in external Green and Yellow Belt creating initial and guiding coalition

- Standardised Customer Journey for greater visibility of value streams and process health

White Belt Awareness to all employees - Programme of variation elimination from Processes and implementation of Process

Management - Launch of Accredited CI Academy for Lean & Six Sigma training

- Implementation of a CI CQAF (Compliance Quality Assurance Framework) evaluation

- Creation of a knowledge bank to centralise the capture of CI projects for the sharing of

information, insight and benefit realisation. - Introduction of Visual Management to provide contractual data insight across Ingeus;

balanced scorecard and dashboard reporting available on contracts to provide insight to

analyse performance and identify what can be done better. - Quarterly Change Agent forums revamped for 2023 introducing a CI channel to ensure two-

way communications and help track improvement projects in progress.

Introduction of communities of practices (Summer 2023) for the sharing of CI Insight, project

success and best practice. - Annual quality appraisal of Academy activity to assess impact, benefits from projects and

value added

The impact

Our approach to continuous improvement has been gradual and as with most continuous

improvement methodologies, we have focussed our efforts on the people who deliver the services

and interact with customers, drawing on their ideas around what will make the experience excellent

and what needs to be improved.

Some of our successful outcomes Included:

Increased maturity from 1 to 4 in Leadership and engagement a result of a supportive and

progressive Executive Board willing to commit to investing in Continuous Improvement for

the future of the business

- Significant increase Lean & Six Sigma accredited Change Agents from 7 employees to 141 to

support and deliver our strategy - Increased CI capability to 5% and above within 98% of teams and an overall capability of 7%

at organisation level - An increase in CI awareness from 32 to 85%

- 6,659 employee views of our CI SharePoint created to provide a central point of information,

tools, and access to training. - More than 1700 people completed White Belt training creating significant awareness around

Standardisation, CI, and Lean Six Sigma - In April 2021 only four (15%) teams were using a centralised process management approach.

As a result of the actions taken as part of the Ingeus CI strategy 30 out of 31(98%) teams are

now using a centralised approach to process management - More than 300 hours of Academy training delivered

Qualitative outcomes - Early engagement with leaders and all staff has created a CI culture where leaders and

change agents drive, promote, and realise the benefits of CI as part of day-to-day work. - Employees develop early understanding of the CI strategy and how they can support

efficiency, effectiveness, and customer excellence. - Employees in key roles now equipped to make better decisions and drive effective change

that balances business risk. - Increased maturity in Compliance & Quality Assurance Framework collaboration

Fiona Monahan, Chief Executive, Ingeus UK

“The last year has proven to be a journey of discovery for Ingeus colleagues. From the Executive and

senior management teams to our talented front-line staff and new starters, we have been guided

and supported into new ways of thinking and working.

“Our Transformation Director Lisa Jasper and her small but mighty team have delivered outstanding

results in the first year of our CI Strategy – their very own masterclass in project implementation.

Feedback to the Executive team has been timely and robust, and our resilient teams have seized

opportunities for uptake.

“We may be a large and somewhat disparate set of teams, delivering multiple contrasting services

with differing demands, yet our uniting purpose to enable better lives can only be strengthened by

fresh thinking, embracing change, and minimising waste, exactly what our CI strategy is now

achieving.”

Ingeus

Background

Ingeus is a leading people services provider, delivering impactful projects to enable better lives at both national and regional level and delivers programmes across the employability, health, youth, and justice sectors. It employs 2,300 people, based remotely and across 100+ UK office locations. In our mission to continuously improve, we launched our three-year Continuous Improvement Strategy in October 2021.

In 2021 Collette was instrumental in launching Ingeus’ Continuous Improvement strategy. She believed this approach would create opportunities for greater collaboration between operational teams and key stakeholders within Ingeus.

Exploration of process management techniques in April 2021 highlighted that only four (15%) teams were using a centralised process management approach.

In addition, an informal opinion poll from existing CI Change Agents in November 21 highlighted that 36 per cent believed their teams’ processes were not centrally managed and 17 per cent were undocumented. Initial Promapp licence capture also highlighted that of 2700 licences, only 477 (18 per cent) were being used and if left unaddressed, this may have resulted in a wasted cost of £33,132.16.

Activity

An improvement project was undertaken by Collette Westerman, Continuous Improvement Academy Development Manager, as part of an ambitious three-year CI strategic plan and its aim was to eliminate variation and siloed process development, to introduce standardise approaches to process mapping process analysis and ensure at least 85 per cent of teams were centrally capturing baseline processes for ongoing improvement.

Actions taken included:

- An enterprise level launch of a centralised process management system

- Implementation of a process management framework

- Launch of a standardised customer journey to help teams visualise existing and required processes

- Process standardisation scoping exercise to help teams capture their process and identify gaps and improvements

- Awareness and Leader Engagement sessions – including breakout sessions on standardisation

- Awareness and training was supported by a newly launched internal CI Academy and a programme of standardisation training using Lean Six Sigma accredited Change Agents as mentors.

Impact

As a result of the actions taken as part of the Ingeus CI strategy 30 out of 31 teams are now using a centralised approach to process management and the project has significantly improved process activities including increased levels of interaction with centralised processes, overall process quality, and visibility and reducing duplication and variation. Some of the additional impacts include:

- Promapp System access increased to 77 per cent after just one round of standardisation training.

- Promapp awareness training increased licence uptake by 439 per cent between April 21 and April 22.

- 130 employees appointed process writers following training; all teams now have appointed process owners increasing accountability for ongoing management and improvement.

- System training through the Academy has increased Promapp interaction/Process views by 998 per cent between April 21 and April 22. A year on, this increase stands at 2,881 per cent.

- 50 processes centrally captured in April 21; to date there are 861 processes.

- Using Promapp allows colleagues to receive an immediate update when there has been a process change – meaning communication around changes is now much quicker.

- Silo working has decreased significantly and teams work collaboratively with stakeholders.

- Teams are joined up in their approach to new starter training – Learning and Development has access to ‘single truth’ operational processes that support accurate induction training.

- Reduction in duplication, variation, firefighting – giving time back to managers because their teams have the information needed to do their job.

Speak Greek®

Background

As there were many Greek tutors offering private or group lessons to students who would like to learn Greek, I tried to identify my unique selling point which I summarised to the motto: ‘Passion for teaching our native language’. Being passionate about my business and equipped with data from analysing what competitors were offering at that time and what customers would like to see on offer, I decided to expand services for customers (students, teachers-competitors, parents, businesses).

Services included free conversation classes for adults, support groups for Greek language & Culture, ebooks, webinars, educational projects, free resources. Despite the range of services available, the number of new students was limited and since 2018 that I included translation services, I found it really hard to attract new customers.

Activity

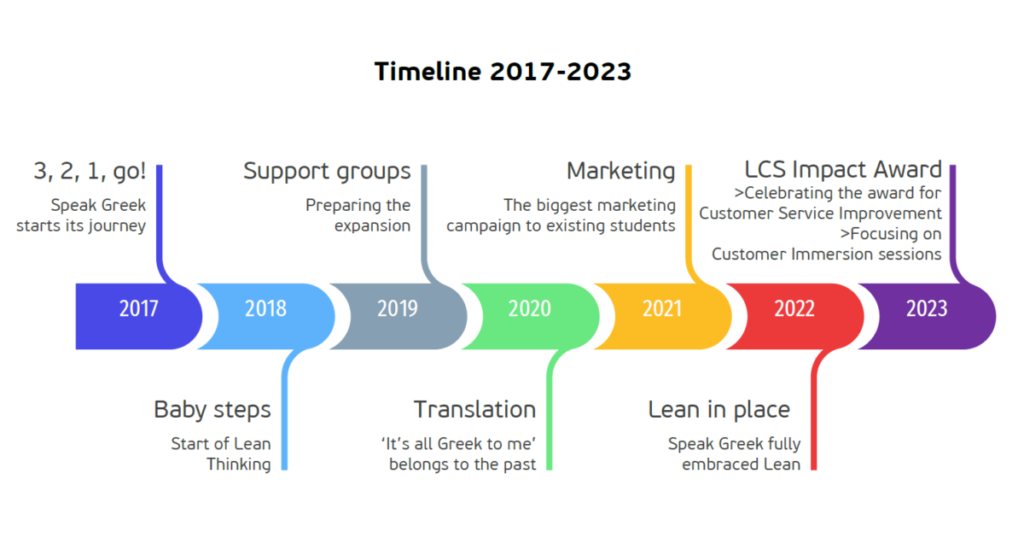

Experiencing lean thinking started in 2018 but a structured approach towards its tools and techniques evolved later. Within the last 12 months lean was fully embraced to all the operations and lessons. To identify why there wasn’t a steady increase of students to take up my services, I used cause and effect diagram.

Through this process, I managed to visually present myself with areas that required improvement with an immediate action plan. To identify how I could be more competitive in the translation industry as there were more established translators than me with more experience and qualifications specifically for translating services, I used A3 problem solving.

I had to attract some of their customers and new customers by adapting an ambitious approach offering competitive charges that included as standard completion of translation within 24 hours, paid 1st class postage and scanned documents to customers. Once I had more students enrolling to either private lessons or classes, I used flow for adult students to identify clearly how I can support customers through a transition period of limited time for myself to be able to deliver lessons.

Impact

By fully immersing myself to lean thinking, Speak Greek® now has a steadily increased income and visitors on the website. Processes that could be automated (enrolling new students, replying to messages with simple queries about availability and prices, scheduling lessons, issuing invoices etc.) are now automated saving a considerable amount of time that is invested in improving quality of services and developing new services.

Also, standardisation of forms (e.g. GDPR consent, Registration form) and fact sheets has led to a reduction of errors and satisfied customers who are becoming our Ambassadors, introducing new customers to our services. Customers are receiving a tailored service and they appreciate the hard work we are putting in to deliver our services.

They also enjoy our commitment to reply to any messages within 24 hours regardless of bank holidays or festive periods/holidays. Customers’ feedback on TrustPilot is amazing, highlighting both the quality and cost-effectiveness of our services: https://uk.trustpilot.com/review/speak-greek.com

Recently, Speak Greek won the SME News Northern Enterprise Award ‘Best Greek Language & Culture Lessons Provider – North West’. Next steps include collaboration with qualified teachers to deliver webinars on specific topics, publishing ebooks of other teachers and introducing customer immersion sessions to become even better!

Hilti Global Logistics Organization

LCS Impact Award: Engaging people and creating value through lean upskilling

Background

Hilti stands for quality, innovation, and direct customer relationship. With more than 32,000 employees in more than 120 countries, the family-owned Hilti Group supplies the worldwide construction and energy industries with technologically leading products, systems, software, and services with the sole purpose of making construction better. Continuous improvement is implicit in the company purpose and the company has a caring and performance-oriented culture as a strategic foundation. This has allowed Lean activities to grow and develop throughout the company in the last years. At the beginning of 2022, the company’s Lean upskilling program was accredited by the LCS. The program uses the 70-20-10 approach: After a self-learning and training sessions, learners are required to demonstrate knowledge and practical capability delivering continuous improvement projects at different levels. This created a great opportunity to motivate employees to engage in continuous improvement activities and the Global Logistics Organization at Hilti decided to use it to accelerate their lean journey and create value (economic impact, customer experience improvement, CO2 reduction, H&S) for the customer and the business.

Activity

The global logistics management team took the decision to deploy the program worldwide and took some key decisions and actions.

- Clear upskilling expectations for regions and functions were defined, agreed, and communicated.

- The program was deployed trough assigned global and regional trainers with clearly defined R&R

- Clear selection criteria for participation were established, trainings scheduled, and mentors assigned.

- Employees participating in the programs were responsible to deliver lean projects according to their level.

- A global steering board has been put in place to frequently review the progress.

- Recognition activities have been organized to celebrate results and certifications.

- An award was designed to recognize the best performing region globally at the end of the year: The living Lean Award

- The program was running throughout 2022 and results were summarized at the end of the year.

Impact

The program received great acceptance from leaders and team members and after one year the global logistics organization achieved results that exceeded the original expectations:

- The upskilling program has been deployed in all 10 geographical regions through local / regional trainers.

- LCS approved trainers’ certificates given to 11 trainers in the regions.

- More than 150 leaders and team members were certified in at least one of the levels.

- Over 650 employees (Around 40% of the total global logistics population) were involved in CI activities.

- This created an overall impact of 5M+ CHF. Doubling the previous year result.

- Employee engagement score increased significantly in regions which exceled in program deployment.

- Living Lean Award granted to the region with the best performance.

World Courier – New Hyde Park

Background

Building on its world-class business model, World Courier kicked off the Center of Excellence (COE) initiative at the beginning of 2022. The program focused on standardizing and improving product workflows focusing on the New Hyde Park (NYC) station. There was significant variation in processes to deliver customer product that utilized the same packaging containers.

This variation had been observed in the inconsistent level of documentation regarding work instructions impacting team member training. The operational variation coupled with other factors resulted in a wide range of performance between stations leading to dramatic variations in customer satisfaction impacting financial performance. Business metrics and visual management to track current performance was not at the level to drive clear actions, identify root causes, and implement effective countermeasures limiting the opportunity for improvements impacting customer satisfaction.

The continuous improvement efforts driven by the COE initiative has dramatically impacted operational performance at New Hyde Park and made it one of the leading stations in the network. Continuous improvement is now becoming “the way we do work” at New Hyde Park and is the foundation to create the World Courier Way. The next step is to roll out the initiative to every station around the world.

Activity

The focus of the COE initiative was on how World Courier customer packaging jobs were processed. The team analyzed the end-to-end value stream from initial customer order to package creation to product pickup and finally to delivery of the product. The team worked with various stakeholder groups across the company that were directly involved in the processes or supported the processes, such as Customer Service and Brokerage.

The working group started by developing value stream maps for each of the product workflows to identify waste and flow issues. In every process, the team began to more consistently and accurately capture defect data to drive root causes by creating pareto charts and using Five Whys and Ishikawa diagrams to perform analysis. Next the team brainstormed potential countermeasures to improve, refine, and standardize the operational processes in New Hyde Park. The team created flow in the process by moving workstations, implementing 5S+ at each station, and instituting visual management.

The team updated standard operating procedures and work instructions to standardize the process. The team also implemented pull by instituting Kanban. All team members received Lean training with many attending the AmerisourceBergen Continuous Improvement Basic Course earning the LCS Level 1a certification.

Impact

The impact to the two main customer facing metrics are On-Time Pickup and On-Time Delivery has been dramatic. Over the six-month period of the initiative both metrics have increased over 30% from 60% to 94%. Other impacts include:

- Improved the flow of packaging and implemented the 5S+ approach to reduce waste and optimize productivity as well as tracking the work completed at the site.

- Stepped up efficiencies when assets are returned including GTCs and Dry Shippers. The team also created a model which optimizes the workflow, in return, maximizing the space to improve our productivity.

- Harnessing the visual management approach to significantly improve and increase workflow and defined lanes to process the incoming and outgoing shipments.

- Defined and implemented new dispatch processes to manage pickups and deliveries and improved the workflow to include visual management during the job activities.

- Eliminated dummy gels in packaging process saving $140k and 120 labor hours annually.

- Eliminated two manual checklists saving 320 labor hours annually.

- Reduced errors in the package check-in process, streamlined return assets process, and eliminated supervisor check by separating packaging and return asset product flows.

- Reduced packaging job issues due to temperature monitor defects by 65%.

- Increased team member engagement and pride.

Continuous Improvement Culture & Capability Build

Background

Sellafield Ltd Group Business Services (GBS) is a Multi-Functional Shared Service organisation. Delivering operational services in People (HR), Finance and Administration. Their primary customers are the 11,000+ employees that work for Sellafield Ltd.

Newly formed in 2020, GBS were looking to build on the work started by Nuclear Shared Business Services (NSBS), with a focus on 4 key areas:

- Seeking to transform service performance, efficiency, pace and quality.

- How? Through Service Management, Digital solutions, E2E process improvement, and driving Business Improvement Culture.

- Transitioning focus of capability from transacting to assuring and adding value.

- Seeking to establish credibility and reputation to delivering more of the services they currently deliver, take on new service lines and deliver to new customers.

Summary

- LCS Impact Award category: Team

- Team name: GBS & BI central team, Sellafield Limited

- Award title: Continuous Improvement Culture and Capability Build.

Activity

Paul Dobson, Business Improvement Practitioner at Sellafield, said:

“I made contact with the GBS Lead Team and explained how I would use the Lean Competency System (LCS) programme approach and conceptualise this to support the demand for a GBS wide improvement in performance with a focus on adding value and minimising waste with the aim being to remove obstacles and frustrations within processes.

The GBS Lead Team signed off on the approach and a roll out plan was formulated, recognising firstly the need for a baseline of current levels of Business Improvement tools and techniques in use to be established. They also recognised the immediate need for a capability build within their area and the longer-term requirement for a Business Improvement culture to be embedded in the area.

With regards to the delivery of 1a and 1b, adding some area specific information to the content has proven to be extremely effective. We also wanted all attendees to understand what we expect from a 1b so a role profile was created. All 1b’s were also to have a specific improvement project to work on which would cover at least 75% of workbook content.”

Impact

No other enabling function at Sellafield Ltd has such a focus on Business Improvements and that is down to the work the Central Business Improvements team has completed in collaboration with GBS over the last 12 months; using the LCS approach to successfully build capability and create the culture.

By building capability and creating this culture of Business Improvements, GBS have ensured that they maximise value across the whole organisation; working together with other areas of the business proactively.

Through the 1a and 1b, GBS employees have developed the skills, values, behaviours and culture that will drive performance. The GBS teams have focused on process optimisation and identification of waste, ensuring they perform collaboratively and effectively.

They now have a defined vision and mission which feeds down into design principles with clear links to the Manifesto.

Error rates have reduced; productivity has increased; Team Leaders are no longer spending half their days dealing with problems raised to them and the introduction of SQCDP has brought multiple benefits across all teams.

130 GBS employees have attended the 1a and 10 employees have completed their 1b modules. 2 out of the 10 1b’s have been certified as Level 1b Business Improvement Practitioners in line with the Lean Competency system. It is expected the other 8 will be signed off in June 2022. This is impressive as the first 1b module was in November 2021, giving an overall time of between 7 to 8 months from start to completion.

All 1b’s have a project to work on which is specific to GBS and this approach has enabled each workbook to be completed in an average of 4 to 5 weeks in between modules and each project has brought immediate benefits to different areas of GBS.